Wiener Schneekugelmanufaktur

Vienna's Original Inventor of the Snow Globe

1. Identity & Presence

The Original Wiener Schneekugelmanufaktur (Original Viennese Snowglobe Manufacture) is a world-renowned family business and the inventor of the snow globe. The company has produced this iconic souvenir since 1900 in Vienna, establishing a unique tradition of hand-crafted fantasy and artistry. The entire operation - production, office, shop, and museum - is located in Vienna's 17th district at Schumanngasse 87, 1170 Vienna, Austria. Their primary contact is +43 1 486 43 41 or office@viennasnowglobe.at, and their online presence is www.schneekugel.at. In 2025 the Schneekugelmanufaktur is celebrating its 125th anniversary. They offer a wide array of motifs, sizes (25mm, 45mm, 80mm, etc.), and custom designs that capture the charm of Vienna and beyond. Their portfolio also includes products around Austrian New Year’s Eve traditions, such as lucky charms and lead-pouring kits, where the miniatures today consist exclusively of tin or wax.

2. The Origin Story & Key Figures

The story of the snow globe is not one of whimsy, but of scientific curiosity. It began with Erwin Perzy I, a surgical instrument mechanic working in the 10th district of Vienna. Around 1900 Perzy was focused on a practical problem: improving the brightness of Thomas Edison's newly invented electric light bulb for use in surgical operating rooms. Inspired by a technique he observed in a shoemaker's workshop, where a water-filled glass globe (a Schusterkugel) was placed in front of a candle to concentrate the light, Perzy attempted to replicate this effect with an electric bulb. To increase the reflection, he began experimenting with adding particles to the water. His initial tests with glass powder failed as the flakes sank too quickly.

The breakthrough occurred in his mother's kitchen, where he found wheat semolina used for baby food. When he poured this white powder into the water-filled globe, the soaked flakes sank slowly and gracefully to the ground. When he saw this, it reminded him instantly of a gentle snowfall.

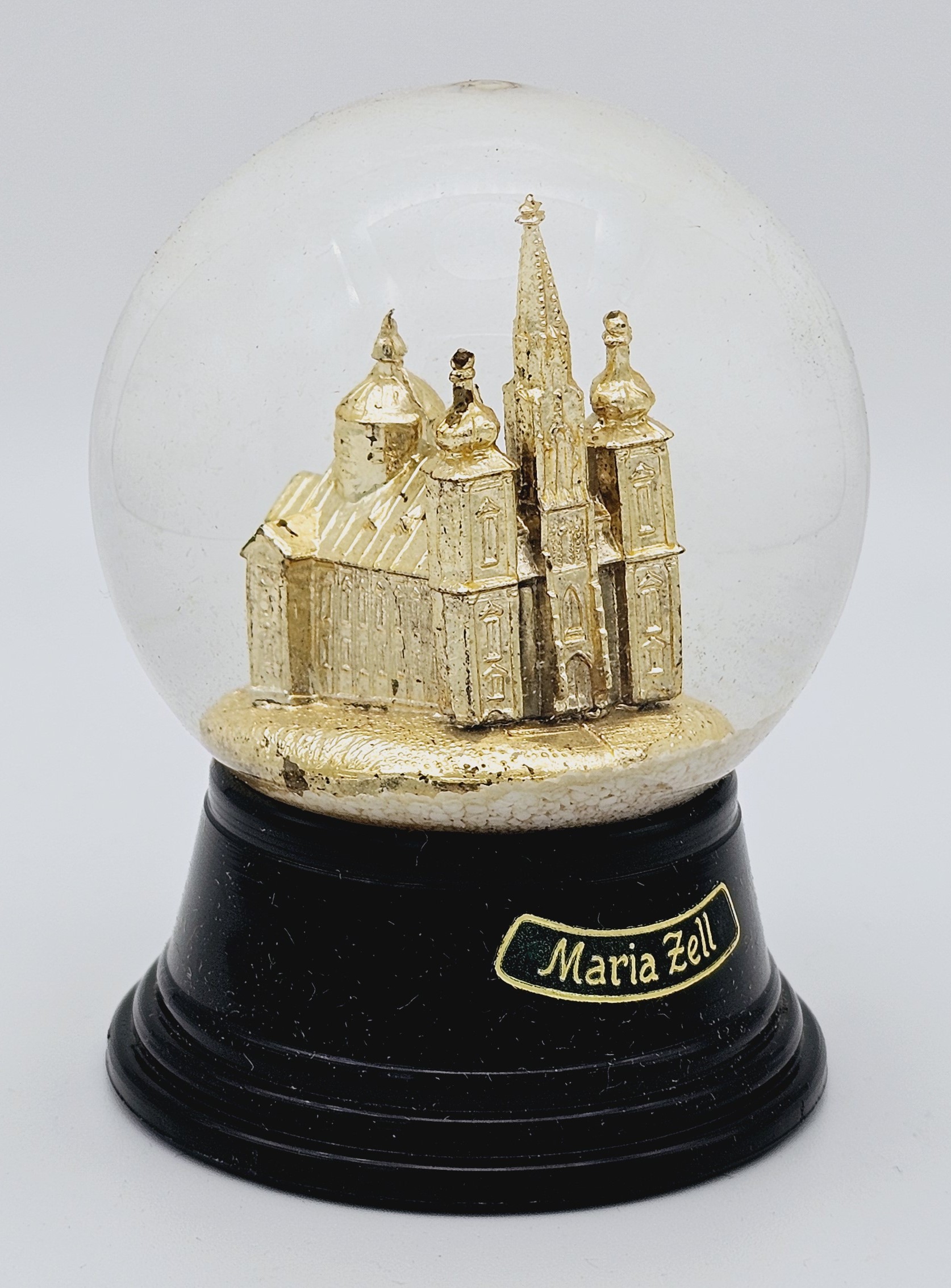

Simultaneously, Perzy was producing miniatures of the Basilica of Maria Zell for a friend who sold them at the pilgrimage site. Abandoning the surgical light project, he combined his two endeavours, placing one of the tiny Mariazell models into the water-filled globe with the semolina. This combination resulted in the world’s first "Glaskugel mit Schnee-Effekt" (glass globe with snow effect), which he successfully patented in 1900.

Erwin Perzy I is also credited with inventing the New Year's lead-pouring tradition at the same time as the snow globe. Inspired by this old custom where pure lead was used, Perzy sought an easily melting alloy that could be liquefied with a simple candle flame. He successfully achieved this with a tin alloy.

The unique artistry and patentable idea of the snow globe established the foundation for the family enterprise, and this manufacturing tradition was subsequently passed through four generations. The Perzy family history is characterized by a strong succession of technical and artistic expertise, ranging from surgical instrument mechanics, toolmaking, and electrical engineering to lettering art and international business. Erwin Perzy II took over the operation after the Second World War, significantly expanding the business and initiating exports to America, Canada, and Australia. Today, the company is led by the fourth generation: Sabine Perzy II, the great-granddaughter of the inventor, who took over management in 2020, and her father, Erwin Perzy III, who remains actively involved in the work.

3. The Core of the Craft

The Original Viennese Snow Globe is defined by the enduring commitment to its original method, ensuring that each piece is a unique work of art through a blend of heritage tools, precision technology, and hand-crafting.

Manufacturing Principles & Process:

- Historical Tooling: The original workshop showcases the evolution of the craft, including Erwin Perzy I's foot-powered milling machine for making metal moulds and the lathe used by Erwin II and III between 1960 and 1990.

- Proprietary Formula & The Signature Snow Fall (The "Nonesuch" Effect): The secret to the globe's magic is the proprietary mixture of the snow. The composition, which is a closely guarded family secret (though known to include specialized plastic and wax components), is no longer based on the original semolina or ground rice. This unique formula achieves a distinctive, perfect, slow-falling effect that can last up to two minutes, depending on the globe's size. This unparalleled quality has led to the common customer claim that it is the "only snowglobe in which it really snows," setting it apart from all global imitations. The Perzy family has historically declined numerous lucrative offers to purchase this secret recipe, ensuring the uniqueness of their product remains protected.

- Precision Casting & Materials: While Erwin Perzy I originally cast all figurines using a tin-lead alloy, the company transitioned to modern plastic injection after World War Two under Erwin Perzy II, which allowed for parts in different colours and easier assembly. Today, the factory utilizes four plastic injection machines and over 1,000 moulds, producing approximately 1.5 million parts annually, using a high percentage of recycled plastic.

- Handmade & Decoration: Every globe remains largely handmade. Home workers assemble the parts and paint the figurines with acrylic varnish. Once sealed in the globe, the contents appear approximately 30% larger due to the glass globe's magnification effect, requiring meticulous painting.

- Water Quality: The factory remains at its Schumanngasse location because it is supplied with pure, high-Alpine water directly from the Hochschwab Mountain, which is essential for preventing bacteria growth and discoloration inside the globes.

4. Enduring Legacy & Resilience

The company’s enduring legacy rests not only on its status as the inventor but also on the unwavering commitment to craft that elevates each globe into a unique work of art, far surpassing common souvenir kitsch. Despite countless global imitations, the Original Viennese Snow Globe remains the worldwide standard, recognized specifically for the unmatched quality of its unique snow effect. This global reputation for excellence was cemented early on when the Schneekugel made its way to Hollywood in the 1940s. The Original Viennese Snow Globe was prominently featured in the opening scene of Orson Welles’ 1941 classic film, Citizen Kane. A journalist later traced the globe's origin back to Perzy I, inspiring a replica. Initially painted in bright colours, the design was successfully re-created in shades of grey after a customer pointed out the original only appeared in a black-and-white film, leading to a large order of 6,000 pieces. The globes have since been featured in other famous movies and TV shows, including Home Alone, True Lies, Edward Scissorhands, and Nine and a Half Weeks.

The four generations of stewardship have guaranteed the preservation of the original manufacturing processes while driving the company's market success. The Manufaktur has proven its resilience by successfully transitioning from a local craft invention to an internationally exported souvenir and collector's item, with major markets in the US (initiated by Erwin II post-WWII) and Japan (their largest export market), following a key partnership with the Mitsubishi company.

5. Vision for the Future

The contemporary vision for the Manufaktur is one of selective innovation and continued tradition, supporting both mass-market and highly customized production.

- Scale and Customization: The standard line offers 350 different designs in four main sizes (25, 45, 80, and 120mm), with 200mm globes reserved for special orders. The Manufaktur handles custom orders ranging from single pieces to thousands, securing high-profile commissions such as commemorative globes for Presidents Reagan, Clinton (using inauguration confetti), and Obama, as well as corporate clients like Coca-Cola, Hotel Sacher, Chopard, and Versace.

- 3D Printing & Tooling: Since 2020, modern technology has been adopted strategically. The toolmaker shop uses CNC mirroring and electric discharging to create approximately 10 moulds annually, supplemented by 10 dedicated 3D printers. This modernization is overseen by Markus Perzy, Sabine's husband and an electrician by trade, who operates the machinery, successfully integrating digital precision with the traditional craft, primarily for custom mould designs.

- Modern Motifs: The Manufaktur stays relevant by creating current trend motifs, such as the highly popular toilet paper globe during the 2020 lockdown and designs featuring classic Viennese sweets like the Sachertorte.

This approach ensures the Manufaktur honours the classic designs that celebrate Vienna while embracing the future with novelty and customized artistry.